Infrastructure

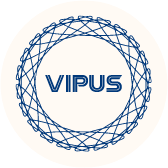

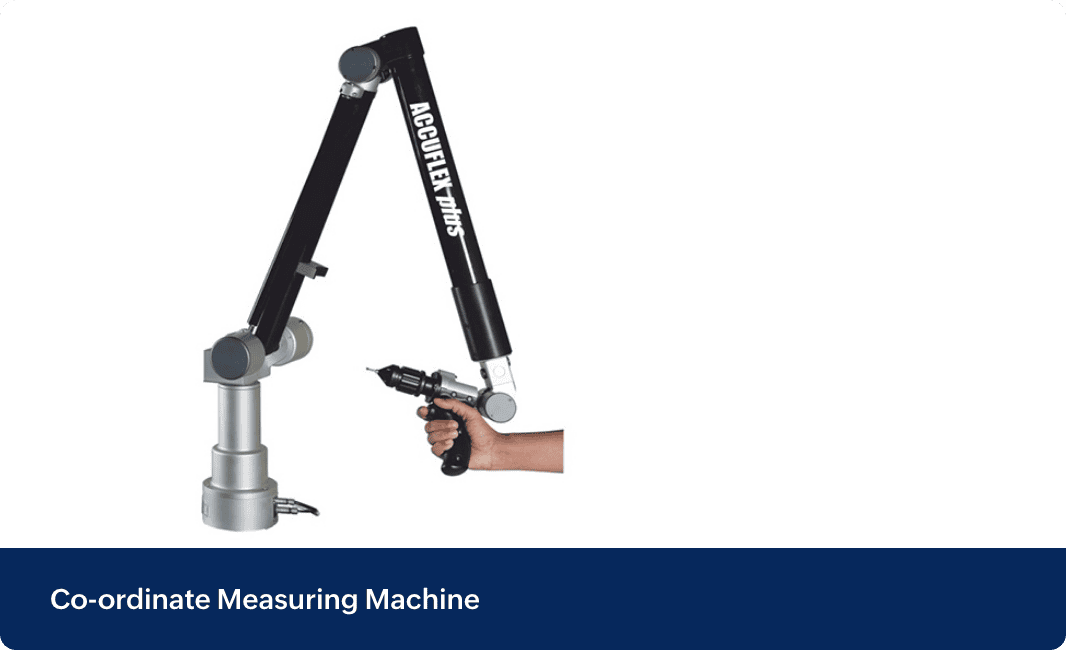

At Vipus Advanced Materials Pvt Ltd, we proudly showcase our state-of-the-art 30,000 sq.ft. facility, a dynamic hub equipped with world-class technology and cutting-edge equipment, dedicated to crafting exceptional composite structures for critical applications.

Our passion for innovation drives us to push boundaries, delivering lightweight, durable, and high-performance solutions that empower aerospace, defense, and industrial markets. Committed to serving our clients with unwavering dedication, we uphold the highest standards of quality, ensuring every product reflects precision, reliability, and excellence. Vipus is here to transform the future of advanced materials, fueling progress and exceeding expectations with every project!